stangflyer

I like 'em "BIG"!

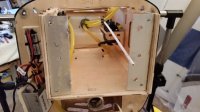

It happens to the best of us. The fact is, the odds are stacked against us. We may slide for a couple of days, weeks, months or even years. But eventually it catches up to us. Such is the case of my little 30% Pilot Edge this past Sunday. I decided to take the Sukhoi and my Pilot Edge to the field for an "ALL" day flying session. Fly the Suhkoi, Beat the tar outta the Edge. Fly the Sukhoi, beat the tar outta the Edge some more. So I was down on the deck in a perfect hover. Just an inch or two from disaster. Never know about these early Spring sudden gusts of wind. I found out rather quickly they are just not fun. One hit the Edge just as I was hovering it and just being one with the plane. I pushed out on the elevator to counter the wind gust. Ooops.... too much. Pulled back.... ooops.... Rudder grabbed the ground and cartwheeled the Edge. I was really expecting to see many of pieces shattered as I walked over to the upside down airframe. Much to my astonished amazement, it was in one piece with no parts hanging off of it. Well, until I looked a little closer. Still, I absolutely know it could have been so much worse. Outside of a disembarked Aileron balance tab, broken Rudder, and motor not looking as though it was sitting correctly, I thought it faired pretty well.

So, now we began fixing an "Ooopsie". I am beginning this thread to perhaps help some of the newer to this hobby flyers. I hope to pass on just a little to help. And to others that may be interested as well.

First the damage!!

So, now we began fixing an "Ooopsie". I am beginning this thread to perhaps help some of the newer to this hobby flyers. I hope to pass on just a little to help. And to others that may be interested as well.

First the damage!!

Last edited: