GSNadmin

Staff member

MAN contributors and readers are a clever bunch, and they’re always coming up with easier, more efficient ways to build and set up airplanes. Here are 8 workshop tips that we think you’ll enjoy using. Have a tip of your own you’d like to share? Send us an email at MAN@airage.com.

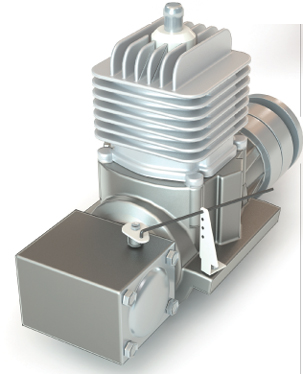

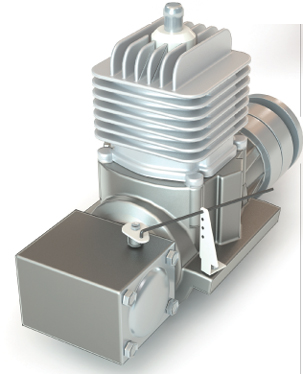

Simple Pushrod Guide

I don’t always want to install a servo to operate the choke on my gasoline engine; in fact, many times I’d rather have a manual choke. The issue becomes controlling the push/pullrod’s location so I can operate it when the cowl is installed on the plane. I found the answer in my parts box: an old nylon control horn. By enlarging the hole, I was able to use the motor mount bolt to secure the control horn to the motor mount, and then use one of the control horn base holes as a guide for the pushrod. Since it is made of nylon, there is almost no friction and no RF noise to bother the ignition of the engine or receiver. It’s very simple to make, install, and works very well.

Cheap Sanding Files

Next time you get paint at the hardware store, be sure to get some extra paint stirrers. Glue strips of sandpaper of various grades to each side of the sticks; 3M 77 spray adhesive works great for this. You can also use sticky-back sandpaper. Now you have created a collection of useful sandpaper files! I find it’s also helpful to mark the sandpaper grit on the handle of the stick for easy reference.

After the Delivery

Don’t throw away those pizza boxes — they make great wheel chocks when transporting your favorite fuselage. Just cut holes to fit the tires —the plane size is only limited to the span of the pizza box. If you have carpet, such has the back of a car or a van, use some hook-and-loop fastener to keep the box and plane fuselage in one spot.

Parting Trick

The protective backing on some covering films can be difficult to separate at first. A strip of masking tape applied to each side of the covering creates a handle on which to pull the sheets apart. Once you try it, you will never go back to separating them with your fingernails.

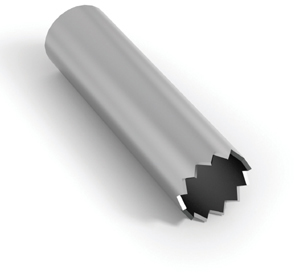

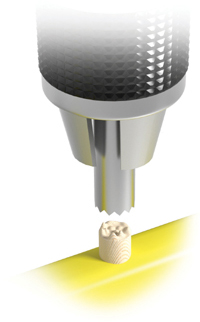

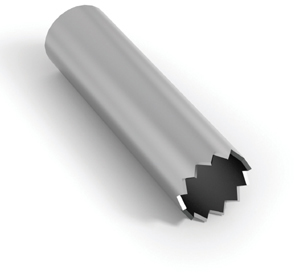

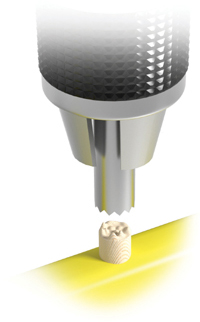

Replace broken dowels and screws

By using a hollowed-out drill bit, you can remove a broken dowel such as one used in the leading edge of the wing. First, find a piece of metal tube that can slide over the broken dowel. File cutting teeth in one end of the tube and then insert the other end in your drill. Use this to “core out” the broken stub. Use this same method to remove broken-off screws. Now just glue in a larger dowel and adjust the mating size hole or sand the dowel flush with the surrounding area and re-dill for the same size dowel you removed.

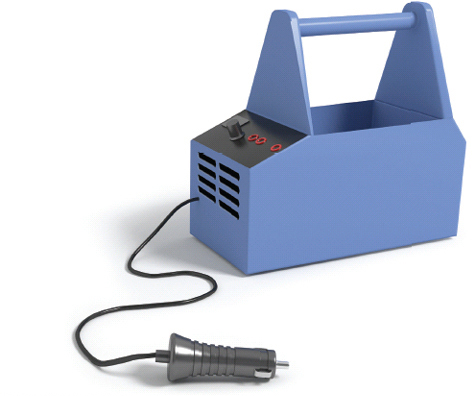

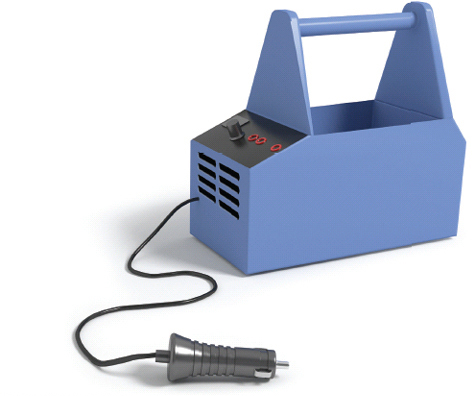

Powering up flight boxes

I’m pretty good at remembering to charge everything before heading to the field, transmitters, receivers, etc. However, I often overlook the flight box since it doesn’t need to be charged every time. This also means it’s dead when I needed it most. My solution was a “cigarette lighter plug” wired into the flight box. Now I can just plug it into the car while driving to or from the flying field. It is always charged and ready to go — problem solved!

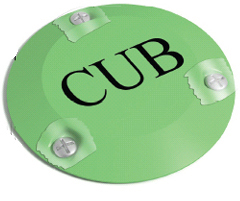

Little screws, big trouble

I thought of this trick when putting the very small and very hard to handle tiny screws into my Cub hubcaps. First I used a pair of tweezers, but the screws were hard to handle and would drop and fall off my bench onto the floor. I would spend more time looking for them then it would take to install them. Then I placed the screws into the holes and put a piece of clear tape over them. This would hold them there while I placed the hubcap down onto the tire. Now I can easily start the screw by poking the screwdriver through the tape and turning them. This worked very well and will work on any little screws that need to be put into a pre-drilled hole.

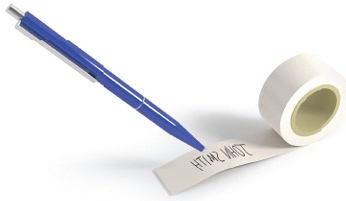

Transparent labels

You never know when your model might get away from you, and per AMA rules, you need to have an address label inside the plane. You also want a label near your charging jack with the size and type of flight battery you have installed. If you don’t have a label maker, here is a simple way to make a transparent label. Using a ballpoint pen, write on the adhesive side of the tape. The trick is to write backward, which is not as hard as you think. When you attach the label to the model, every word will read correctly and be protected from the elements.

Model Airplane News - The #1 resource for RC plane and helicopter enthusiasts featuring news, videos, product releases and tech tips.

Continue reading...

Simple Pushrod Guide

I don’t always want to install a servo to operate the choke on my gasoline engine; in fact, many times I’d rather have a manual choke. The issue becomes controlling the push/pullrod’s location so I can operate it when the cowl is installed on the plane. I found the answer in my parts box: an old nylon control horn. By enlarging the hole, I was able to use the motor mount bolt to secure the control horn to the motor mount, and then use one of the control horn base holes as a guide for the pushrod. Since it is made of nylon, there is almost no friction and no RF noise to bother the ignition of the engine or receiver. It’s very simple to make, install, and works very well.

Cheap Sanding Files

Next time you get paint at the hardware store, be sure to get some extra paint stirrers. Glue strips of sandpaper of various grades to each side of the sticks; 3M 77 spray adhesive works great for this. You can also use sticky-back sandpaper. Now you have created a collection of useful sandpaper files! I find it’s also helpful to mark the sandpaper grit on the handle of the stick for easy reference.

After the Delivery

Don’t throw away those pizza boxes — they make great wheel chocks when transporting your favorite fuselage. Just cut holes to fit the tires —the plane size is only limited to the span of the pizza box. If you have carpet, such has the back of a car or a van, use some hook-and-loop fastener to keep the box and plane fuselage in one spot.

Parting Trick

The protective backing on some covering films can be difficult to separate at first. A strip of masking tape applied to each side of the covering creates a handle on which to pull the sheets apart. Once you try it, you will never go back to separating them with your fingernails.

Replace broken dowels and screws

By using a hollowed-out drill bit, you can remove a broken dowel such as one used in the leading edge of the wing. First, find a piece of metal tube that can slide over the broken dowel. File cutting teeth in one end of the tube and then insert the other end in your drill. Use this to “core out” the broken stub. Use this same method to remove broken-off screws. Now just glue in a larger dowel and adjust the mating size hole or sand the dowel flush with the surrounding area and re-dill for the same size dowel you removed.

Powering up flight boxes

I’m pretty good at remembering to charge everything before heading to the field, transmitters, receivers, etc. However, I often overlook the flight box since it doesn’t need to be charged every time. This also means it’s dead when I needed it most. My solution was a “cigarette lighter plug” wired into the flight box. Now I can just plug it into the car while driving to or from the flying field. It is always charged and ready to go — problem solved!

Little screws, big trouble

I thought of this trick when putting the very small and very hard to handle tiny screws into my Cub hubcaps. First I used a pair of tweezers, but the screws were hard to handle and would drop and fall off my bench onto the floor. I would spend more time looking for them then it would take to install them. Then I placed the screws into the holes and put a piece of clear tape over them. This would hold them there while I placed the hubcap down onto the tire. Now I can easily start the screw by poking the screwdriver through the tape and turning them. This worked very well and will work on any little screws that need to be put into a pre-drilled hole.

Transparent labels

You never know when your model might get away from you, and per AMA rules, you need to have an address label inside the plane. You also want a label near your charging jack with the size and type of flight battery you have installed. If you don’t have a label maker, here is a simple way to make a transparent label. Using a ballpoint pen, write on the adhesive side of the tape. The trick is to write backward, which is not as hard as you think. When you attach the label to the model, every word will read correctly and be protected from the elements.

Model Airplane News - The #1 resource for RC plane and helicopter enthusiasts featuring news, videos, product releases and tech tips.

Continue reading...