cam4569

70cc twin V2

Ok so as I was looking for another (backup) indoor flier I came across this Hobbyking EPP plane. for 41 dollars I figured it was a decent deal and worth a shot. Total with all the extras needed this plane can be built for under 75 dollars, not bad when the last EPP plane I built cost double that.

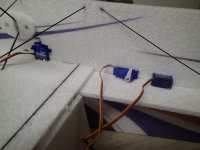

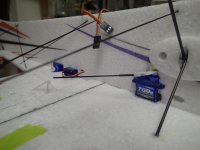

I already had the RX and the ESC that was listed as needed on the website so that brought my cost down. I did order a couple packages of props and 4 servos (one extra because I have seen some of the cheaper ones not work out of the box).

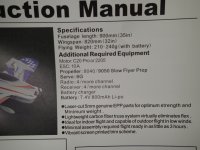

That being said here are the specs as listed online

Spec.

Fuselage length: 900mm

WingSpan: 820mm

ARF Weight: 210 - 240g

Included ;

Motor : 1500kV Brushless outrunner

Airscrew : 9050 slow flyer

Required ;

Battery : 2S~3S 800mah 15C

Servo : 3 x 9g

ESC : 18A

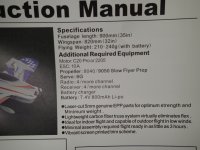

The manual doesn't match up:

The manual calls for a 10A ESC also the motor in the box has no markings on it so I wonder if what was included in the box is what was advertised online or what the manual states. I have an 18A ESC on hand so we will see if the motor will turn the 9" prop once installed.

The box arrived within 3 days of placing the order, I was surprised however that the one box had my entire order just tossed on top of the plane

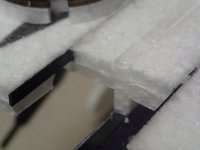

The plane itself was tapped down (a lot) when un-boxing you will need a sharp knife to cut through all the clear packaging tape that is holding every piece to the box. I should say each piece is also wrapped and sealed in plastic.

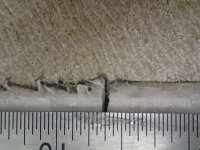

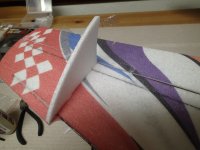

The plane looked to be cut well, all the pieces have clear indents where you need to cut to attach everything together. The elevators and ailerons are attached to their respective wings/stabilizer you will need to cut these off to attach the hinges but like I said they are pre cut so will be easy to remove. The foam is 3mm thick so I expect this will be a fairly light plane once built, I am curious if it will hold up as well as my other higher priced brand EPP planes.

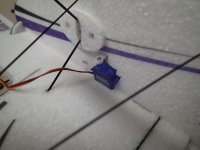

A note about this plane: if you have not built an EPP or a plane before this doesn't appear to be a good one to start on. there are a lot of small parts and the manual is not great. lining everything up and making it square may be a challenge at best. After perusing through the manual there are a few things that don't make sense to me on the build so I will use it more as a "guide" than an step by step manual. The first thing is that it recommends CA for everything, I will be using Welders for most of this build as I have had good luck in the past with it on EPP.

I will come back and update this thread as I work on the plane, it is not a priority at this point but should be done in about a week or two. If you have any questions I would be glad to attempt to answer...

I already had the RX and the ESC that was listed as needed on the website so that brought my cost down. I did order a couple packages of props and 4 servos (one extra because I have seen some of the cheaper ones not work out of the box).

That being said here are the specs as listed online

Spec.

Fuselage length: 900mm

WingSpan: 820mm

ARF Weight: 210 - 240g

Included ;

Motor : 1500kV Brushless outrunner

Airscrew : 9050 slow flyer

Required ;

Battery : 2S~3S 800mah 15C

Servo : 3 x 9g

ESC : 18A

The manual doesn't match up:

The manual calls for a 10A ESC also the motor in the box has no markings on it so I wonder if what was included in the box is what was advertised online or what the manual states. I have an 18A ESC on hand so we will see if the motor will turn the 9" prop once installed.

The box arrived within 3 days of placing the order, I was surprised however that the one box had my entire order just tossed on top of the plane

The plane itself was tapped down (a lot) when un-boxing you will need a sharp knife to cut through all the clear packaging tape that is holding every piece to the box. I should say each piece is also wrapped and sealed in plastic.

The plane looked to be cut well, all the pieces have clear indents where you need to cut to attach everything together. The elevators and ailerons are attached to their respective wings/stabilizer you will need to cut these off to attach the hinges but like I said they are pre cut so will be easy to remove. The foam is 3mm thick so I expect this will be a fairly light plane once built, I am curious if it will hold up as well as my other higher priced brand EPP planes.

A note about this plane: if you have not built an EPP or a plane before this doesn't appear to be a good one to start on. there are a lot of small parts and the manual is not great. lining everything up and making it square may be a challenge at best. After perusing through the manual there are a few things that don't make sense to me on the build so I will use it more as a "guide" than an step by step manual. The first thing is that it recommends CA for everything, I will be using Welders for most of this build as I have had good luck in the past with it on EPP.

I will come back and update this thread as I work on the plane, it is not a priority at this point but should be done in about a week or two. If you have any questions I would be glad to attempt to answer...

Last edited by a moderator: