GSNadmin

Staff member

Every issue we share reader advice in our “Tips & Tricks” column. Here are a few of our favorites.

STAR STRUCK

Cutting out very small stars is nearly impossible with a hobby knife, and no small pre-made stars are available, either. My son and I have found the perfect solution: star-shaped punches for scrapbooking available at craft stores. Sizes range from as small as ⅜ inch up to about 1 inch across. Simply take a piece of your covering (I use MonoKote), peel the backing sheet off and punch out as many as you need. I use a Sharpie marker to make lines on the shiny side. The other is the glue side, so ironing them in place is easy as the marks on top can be cleaned off with acetone.

NO-STICK MIX

This is a great tip from way back. Coffee-can lids are made of smooth formed plastic that two-part epoxy glue won’t stick to. Just apply equal amounts of part A and B epoxy and mix together. After you’ve glued your parts together, set the lid aside. Once the adhesive has cured and hardened, it can easily be peeled away, leaving a clean surface to use again. This is much better than using disposable mixing cups that can tip over.

NEAT SEAMS

When you cover a model airplane part like a wing or tail surface, keeping the edges and seams straight adds a lot to the overall clean appearance. A great covering job with sloppy seams will not look as good as an average job with straight, neat seams. A surefire way to do this on the cheap is to simply stick your blade through a scrap block of hard-grain balsa wood. Position the blade about a 1/4 inch from the block’s edge with the tip protruding about 3/16 inch below the block. Hold the excess covering taught and run the block/blade around the part to produce a neat, consistent cut. Works every time.

EASY BREATHING

Iron-on film coverings like MonoKote and UltraCote really seal up model structures like wings and control surfaces, and sometimes the heated air inside the structure will expand and the covering will “balloon” because the air has nowhere to escape. When the air cools, the covering becomes slack. Making a small slit in an outer edge with a hobby knife will allow the air to escape easily without marring the model’s looks.

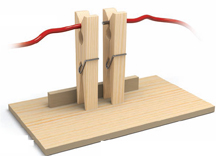

HELPING HANDS

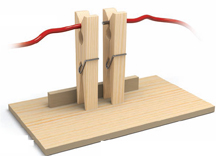

It is darn near impossible to solder connectors to lengths of wire without some sort of holding fixture. You can purchase a jig, but I use what’s at hand on my workbench. Simply glue a couple of clamping clothespins to a wooden base as shown. This arrangement holds the parts together while allowing me to hold the soldering iron and solder to do the job. Best of all, it costs nothing to make.

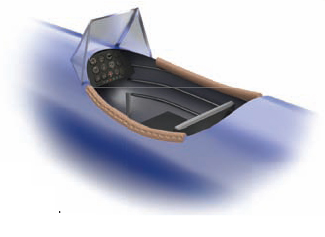

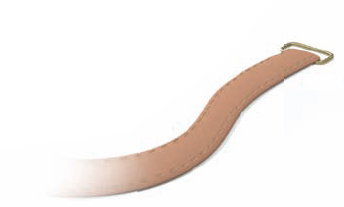

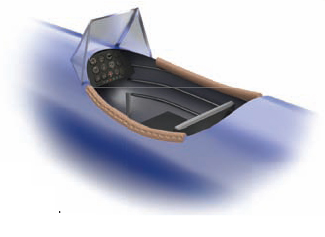

COAMING BY PRADA

For an easy way to make a good-looking leather cockpit coaming for your next open-cockpit airplane, check yard sales for old, worn-out leather handbags. The shoulder straps have nicely stitched and rounded edges and, with a good pair of scissors, you can cut sections of the strap edging free. Cut the section to the size coaming you need and remove the inner core. Cut to length, peel the two edges open and attach to the open edge around the cockpit. Glue in place with a touch of CA adhesive or white canopy glue. Voila!—an inexpensive, easy to fabricate scale detail. You can now proudly say, “My cockpit coaming is a “Louis Vuitton” or a “Prada.”

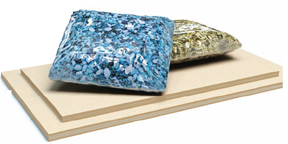

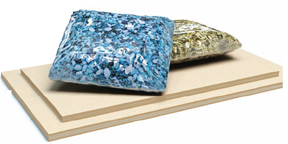

WEIGHT BAGS

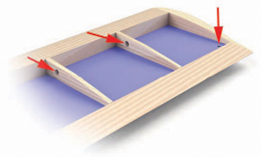

When you have to laminate two large sheets of plywood together, it is often difficult to get a consistent glue bond if you just use edge clamps. I fill up sealable plastic bags with aquarium gravel to make handy weight bags. You can also use sand, but my daughter has lots of fish so I steal the gravel from her.

PROPER BALANCE

I’m old-school and try to save my hobby bucks whenever I can. There are all sorts of propeller balancers out there for sale, but none of them work any better than my old, tried and true technique using single-edge razor blades. Simply get two blocks of wood (balsa or pine will do) and glue them to a sturdy base. On top of the blocks, glue the razor blades vertically (sharp edge up) at the same height and level with each other. Insert a drill rod (or a snug-fitting hobby knife handle) into the propeller hub and place on top of the razor blades. Now balance your propeller. I’ve been doing it this way for many years!

Have a tip to share? Send it to MAN@airage.com (no illustration needed, but it may help to take a photo) for “Tips & Tricks.” If we feature your tip in the magazine, we’ll send you Bob Smith Industries adhesive care package!

Model Airplane News - The #1 resource for RC plane and helicopter enthusiasts featuring news, videos, product releases and tech tips.

Continue reading...

STAR STRUCK

Cutting out very small stars is nearly impossible with a hobby knife, and no small pre-made stars are available, either. My son and I have found the perfect solution: star-shaped punches for scrapbooking available at craft stores. Sizes range from as small as ⅜ inch up to about 1 inch across. Simply take a piece of your covering (I use MonoKote), peel the backing sheet off and punch out as many as you need. I use a Sharpie marker to make lines on the shiny side. The other is the glue side, so ironing them in place is easy as the marks on top can be cleaned off with acetone.

NO-STICK MIX

This is a great tip from way back. Coffee-can lids are made of smooth formed plastic that two-part epoxy glue won’t stick to. Just apply equal amounts of part A and B epoxy and mix together. After you’ve glued your parts together, set the lid aside. Once the adhesive has cured and hardened, it can easily be peeled away, leaving a clean surface to use again. This is much better than using disposable mixing cups that can tip over.

NEAT SEAMS

When you cover a model airplane part like a wing or tail surface, keeping the edges and seams straight adds a lot to the overall clean appearance. A great covering job with sloppy seams will not look as good as an average job with straight, neat seams. A surefire way to do this on the cheap is to simply stick your blade through a scrap block of hard-grain balsa wood. Position the blade about a 1/4 inch from the block’s edge with the tip protruding about 3/16 inch below the block. Hold the excess covering taught and run the block/blade around the part to produce a neat, consistent cut. Works every time.

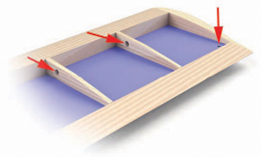

EASY BREATHING

Iron-on film coverings like MonoKote and UltraCote really seal up model structures like wings and control surfaces, and sometimes the heated air inside the structure will expand and the covering will “balloon” because the air has nowhere to escape. When the air cools, the covering becomes slack. Making a small slit in an outer edge with a hobby knife will allow the air to escape easily without marring the model’s looks.

HELPING HANDS

It is darn near impossible to solder connectors to lengths of wire without some sort of holding fixture. You can purchase a jig, but I use what’s at hand on my workbench. Simply glue a couple of clamping clothespins to a wooden base as shown. This arrangement holds the parts together while allowing me to hold the soldering iron and solder to do the job. Best of all, it costs nothing to make.

COAMING BY PRADA

For an easy way to make a good-looking leather cockpit coaming for your next open-cockpit airplane, check yard sales for old, worn-out leather handbags. The shoulder straps have nicely stitched and rounded edges and, with a good pair of scissors, you can cut sections of the strap edging free. Cut the section to the size coaming you need and remove the inner core. Cut to length, peel the two edges open and attach to the open edge around the cockpit. Glue in place with a touch of CA adhesive or white canopy glue. Voila!—an inexpensive, easy to fabricate scale detail. You can now proudly say, “My cockpit coaming is a “Louis Vuitton” or a “Prada.”

WEIGHT BAGS

When you have to laminate two large sheets of plywood together, it is often difficult to get a consistent glue bond if you just use edge clamps. I fill up sealable plastic bags with aquarium gravel to make handy weight bags. You can also use sand, but my daughter has lots of fish so I steal the gravel from her.

PROPER BALANCE

I’m old-school and try to save my hobby bucks whenever I can. There are all sorts of propeller balancers out there for sale, but none of them work any better than my old, tried and true technique using single-edge razor blades. Simply get two blocks of wood (balsa or pine will do) and glue them to a sturdy base. On top of the blocks, glue the razor blades vertically (sharp edge up) at the same height and level with each other. Insert a drill rod (or a snug-fitting hobby knife handle) into the propeller hub and place on top of the razor blades. Now balance your propeller. I’ve been doing it this way for many years!

Have a tip to share? Send it to MAN@airage.com (no illustration needed, but it may help to take a photo) for “Tips & Tricks.” If we feature your tip in the magazine, we’ll send you Bob Smith Industries adhesive care package!

Model Airplane News - The #1 resource for RC plane and helicopter enthusiasts featuring news, videos, product releases and tech tips.

Continue reading...