emtp275

100cc

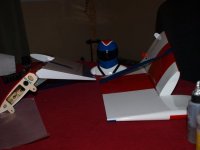

Ok I am going to attempt to document my experience with EF and the building of the 91" Yak. First off I must say buying this airframe was hassle free, It was delivered by Freight which was awesome I had it in two days and the driver is able to contact you for any questions and to set up a time to drop the package off. Miles ahead of getting any thing UPS or FedEx. So it arrives in perfect condition double boxed and the inner box is more like plywood than it is cardboard extremely ridged. All the continence packaged nicely and in an orderly fashion every bag was labeled so no guessing where any thing goes. Gold star so far on customer service and quality of the packing and shipping.