stangflyer

I like 'em "BIG"!

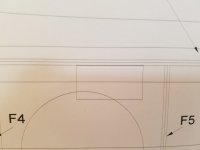

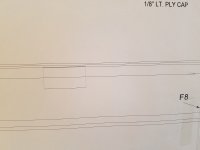

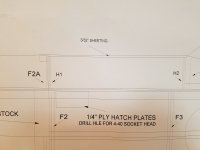

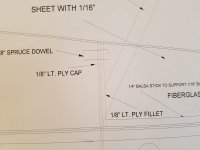

The DS Mustang is looming ever closer and I need to get this done before I can move on to that project. With the Kolm tres cylinder on the way, I know I am not going to want to do anything when it gets here except play with them gorgeous....umm, cylinders. So to do a little catch up, this is what I have gotten accomplished with what little time I have had. Today I basically broke everything out of the plane room and got all set up again. I had to do some catch up reading of the manual and the photo layout. I seen this before, but really didn't like it much. Now, I "REALLY" don't like it much. They way the plans and manual indicates this plane to be built is to have the entire top part of the fuse a removable hatch. That is...the forward hatch, canopy and rear turtle deck come off to expose the entire inside of the fuse.

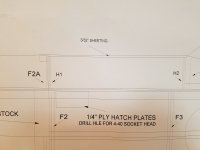

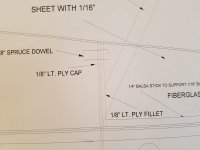

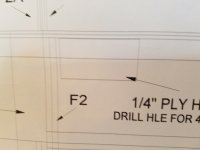

There are 8 locating plates that go in the fuse to hold the hatch/top fuse where it belongs. Along with large dowels in the back of the turtle deck that slides into recesses in the tail. Umm....NO!

I've seen many earlier model built planes this way. I have never liked it so I made a revision to more current model build technics. The rear turtle deck has been glued to the fuselage at the proper location. These photos show the location before setting the turtle deck and gluing it into position.

And now with it glued tightly to the lower fuse.

Along with many other steps completed, I also got the lower tail filler sheeted and the canopy flashing cut off. Yes that is buckshot in the Hitec servo boxes. Great little weights. LOL

There is much more done, but need to find them darn photos. I've had a computer replacement since I downloaded them and I am hoping I can pull them from that old hard drive. If not, I will just take new ones. There is no way I will have the main construction of this plane done before the end of the month. But I am going to try really hard to have it basically done and ready for covering before Christmas. By then the retracts for the Behemoth Stang will be here along with that really cool Kolm. I just really want to get started on the build of that fighter warbird.

More to come....

There are 8 locating plates that go in the fuse to hold the hatch/top fuse where it belongs. Along with large dowels in the back of the turtle deck that slides into recesses in the tail. Umm....NO!

I've seen many earlier model built planes this way. I have never liked it so I made a revision to more current model build technics. The rear turtle deck has been glued to the fuselage at the proper location. These photos show the location before setting the turtle deck and gluing it into position.

And now with it glued tightly to the lower fuse.

Along with many other steps completed, I also got the lower tail filler sheeted and the canopy flashing cut off. Yes that is buckshot in the Hitec servo boxes. Great little weights. LOL

There is much more done, but need to find them darn photos. I've had a computer replacement since I downloaded them and I am hoping I can pull them from that old hard drive. If not, I will just take new ones. There is no way I will have the main construction of this plane done before the end of the month. But I am going to try really hard to have it basically done and ready for covering before Christmas. By then the retracts for the Behemoth Stang will be here along with that really cool Kolm. I just really want to get started on the build of that fighter warbird.

More to come....