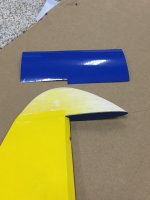

Hinged my rudder and elevators to their stabilizers.

As mentioned before I’m using robart pinned hinges instead of CA hinges. Mainly because I like of much more resilient they are with a gas engine.

Didn’t have too many pictures with the rudder because I am going to start to record video and post it on YouTube after some editing. I have quite a bit of fun editing and positing flight videos but recently I’ve been having an itch to start making and adding “How To” videos to my “AKNick” channel. So stay tuned.

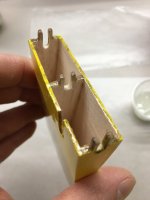

For installing pinned hinges, my process goes like this:

Deplete a carbonated beverage of choice. Flip it upside down and smear some petroleum jelly (Vaseline) in your newly created reservoir. Bust out your heat gun of choice and liquify that jelly. Grab a pinned hinge and bend it to its extreme so you can emerge the pin in the liquid jelly. Bend it the other direction and dip it again. Set aside. The petroleum jelly will solidify as it reaches room temperature again. Presto, now you have a fully lubricated and sealed pin to prevent epoxy from going where you don’t want it ho during the next step.

Using 30min Zap Epoxy, I mix it up in a mixing cup with a small plastic dowel used for rod building finishing resin. Use the rod to coat the epoxy inside the hinge holes. Lightly cover one barbed end of the pin by smearing with the mixing rod and insert into one half of the control surface. Do this with all the pins. You should have little to no excess resin. Do the other side and repeat.

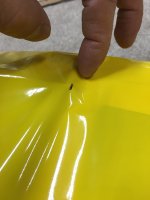

For the excess resin I use 99% isopropyl achohol on cut up paper towels and wipe clean.

Deflect the control surface many times while pushing together. Then tape both sides in place, use alignment boards/devices if you have to in order to keep everything flush. Allow sufficient time to cure, then be amazed of how smooth your control surface moves.

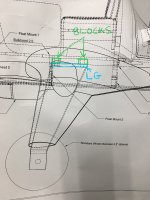

View attachment 117260 View attachment 117261 View attachment 117262 View attachment 117263 View attachment 117264 View attachment 117265 View attachment 117266 View attachment 117267 View attachment 117268 View attachment 117269 View attachment 117270 View attachment 117271 View attachment 117272 View attachment 117273 View attachment 117274 View attachment 117275 View attachment 117276 View attachment 117277 View attachment 117278 View attachment 117279 View attachment 117280