Xpress

GSN Sponsor Tier 1

This post is mostly for my reference so I know what I need to gather or buy for the airplane, but please by all means use it to put yours together!

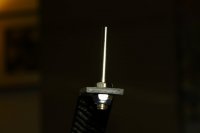

-Desert Aircraft DA70, x1 (CHECK)

-Falcon 24x9 propeller, x1 (CHECK)

-4" spinner, red to match, x1

-Fromeco Sahara 6.0v regulator, x1 (CHECK)

-Fromeco Wolverine switch, x1 (CHECK)

-Fromeco Badger switch, x1 (CHECK)

-Thunder Power 2s 1900 RX pack, x3

-Hitec HSB-9485SH servo, x5 (CHECK)

-Hitec HSB-9465SH servo, x1 (CHECK)

-Hitec Maxima 6 receiver, x2 (CHECK)

-Hitec 36" HD Twisted extension, x2 (CHECK)

-Hitec 12" HD Twisted extension, x4 (CHECK)

-SWB 1.5" Futaba spline arm, x4 (CHECK)

-SWB 1" Futaba spline arm, x1 (CHECK)

-SWB 4" offset Futaba spline arm, x1 (CHECK)

-Secraft easy couplers, x1 (CHECK)

-Secraft wing bolts, x1

I think that's about all I need for the airplane, the hardware included with it is impressive and saves on a lot of the cost..

-Desert Aircraft DA70, x1 (CHECK)

-Falcon 24x9 propeller, x1 (CHECK)

-4" spinner, red to match, x1

-Fromeco Sahara 6.0v regulator, x1 (CHECK)

-Fromeco Wolverine switch, x1 (CHECK)

-Fromeco Badger switch, x1 (CHECK)

-Thunder Power 2s 1900 RX pack, x3

-Hitec HSB-9485SH servo, x5 (CHECK)

-Hitec HSB-9465SH servo, x1 (CHECK)

-Hitec Maxima 6 receiver, x2 (CHECK)

-Hitec 36" HD Twisted extension, x2 (CHECK)

-Hitec 12" HD Twisted extension, x4 (CHECK)

-SWB 1.5" Futaba spline arm, x4 (CHECK)

-SWB 1" Futaba spline arm, x1 (CHECK)

-SWB 4" offset Futaba spline arm, x1 (CHECK)

-Secraft easy couplers, x1 (CHECK)

-Secraft wing bolts, x1

I think that's about all I need for the airplane, the hardware included with it is impressive and saves on a lot of the cost..

Last edited by a moderator: