Ohio AV8TOR

Just Do It

For sure that canopy is a winner. Looking forward to seeing the latch.

From what I've read on-line CF shafts run from 0.275" to 0.400". The ones I used I just looked at in a sporting goods store and thought "that looks about right". There is a whole science of CF arrow shaft stiffness, called "spine" that comes into play in archery. I'm like you though, triggers I know!wesley. said

On the carbon arrow shafts are those all one size or can you get different diameters? I know absolutely nothing about bows i like pulling a trigger!

Neat stuff. If I had know about them earlier they would have been another option. However I'm done fiddling with the canopy....and besides....on the full scale the pilot has to manually unlatch and swing it openOhio.AV8TOR said

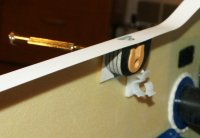

Or linear driven actuator like this ....

If you have a bell crank on the hinge pin that is connected to the canopy the 100mm travel unit should give you 90º of travel