Joe Hunt

150cc

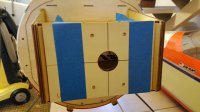

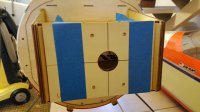

Next I downloaded a template for the engine and transferred that over to the universal wood template AW includes with the plane. I then taped that on the motorbox while lining its alignment lines up with the alignment lines on the firewall. Then I drilled it out for the blind nuts.

After I put in the blindnuts from microfasteners.com I used ZAP thin CA on all the glue joints I could get to throughout the plane. I used to get my ZAP glue directly from Frank Tiano of ZAP glues because it always came so fresh. Once when I got some CA from a hobby store it was so old that it could not glue two pieces of wood together (literally could not). My local hobby store says they get fresh glue in every week so I went ahead and got it locally this time.

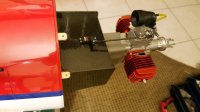

I put the cowl on and the engine was nice and centered:

After I put in the blindnuts from microfasteners.com I used ZAP thin CA on all the glue joints I could get to throughout the plane. I used to get my ZAP glue directly from Frank Tiano of ZAP glues because it always came so fresh. Once when I got some CA from a hobby store it was so old that it could not glue two pieces of wood together (literally could not). My local hobby store says they get fresh glue in every week so I went ahead and got it locally this time.

I put the cowl on and the engine was nice and centered: