You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AJ 93" Laser Reflex build/assembly!!!

- Thread starter Carrid02

- Start date

Alky6

150cc

I can get you data, but won’t be until next week as I am not home. But rough order of magnitudes are 30-40 degrees less. This is based on an EF 78” Extra w VVRC 40cc twin and on the EF MXS with DA 120. I did a lot of testing with various baffling and outlet scenarios on the VVRC (mine) so I have quite a bit of data (in flight). With the MXS, it is my buddies, but it would constantly give him high cylinder temp warnings during flight. We covered up the bottom hole at the field w some tape and temps dropped about 38 (if I recall correctly) degrees and no more high temp warnings. I don’t recall where those temp thresholds were set, but I can ask.Interesting suggestion! I'd love to see some telemetry data on that! Can you post any findings?

I only ask because these AJ airplanes are super popular and that carb hole comes "open" like that from the factory... And I've never seen anyone cover it up for any reason.

-Craig

Take a piece of duct tape when you are at the field and cover it up for a flight. I bet you find a significant decrease in temps.

Alky6

150cc

Haven’t forgot about you and the data. Back home now, will dig through my files this weekend.Man, those are very interesting results. No rush, but I'd love to see your testing/data if you can post it.

Once I get the low pressure lip installed on my plane, I'll fly it and check temp. Then I'll cover the carb hole, fly and check temp again.

Thanks for the info!

-Craig

-Paul

Alky6

150cc

Craig:

Just looking at the hole in front of the carb on the EF 78” extra and the VVRC 40. This was in 2014 when only the inlet holes were directed to the cylinders (typical baffling). Peak temps were 323F. Putting tape over the hole in front of the carb resulted in peak temps of 296F (27 degree reduction). I later changed the baffling to go around the cylinders (see pics below). While the peak temps didn’t change much, I saw a significant change in temps during slower less aggressive flying. Down to the 240F range (previously was in the 270-285 range). The best outlet condition I found was with the dam furthest forward on the cowl. I also tried Louvers over the area just in front of the landing gear. Again, most of the outlet data preceded the latest baffling of the engine. Also, my notes don’t show a significant change in peak temps regarding the different outlet conditions. Only a few degrees. Hope that helps.

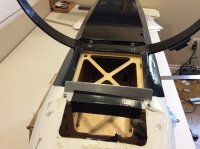

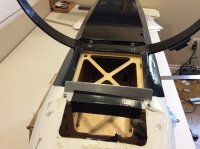

Original baffling - directed to cylinder head:

Examples of different outlet conditions tried:

Latest generation of baffling that was the most effective:

Just looking at the hole in front of the carb on the EF 78” extra and the VVRC 40. This was in 2014 when only the inlet holes were directed to the cylinders (typical baffling). Peak temps were 323F. Putting tape over the hole in front of the carb resulted in peak temps of 296F (27 degree reduction). I later changed the baffling to go around the cylinders (see pics below). While the peak temps didn’t change much, I saw a significant change in temps during slower less aggressive flying. Down to the 240F range (previously was in the 270-285 range). The best outlet condition I found was with the dam furthest forward on the cowl. I also tried Louvers over the area just in front of the landing gear. Again, most of the outlet data preceded the latest baffling of the engine. Also, my notes don’t show a significant change in peak temps regarding the different outlet conditions. Only a few degrees. Hope that helps.

Original baffling - directed to cylinder head:

Examples of different outlet conditions tried:

Latest generation of baffling that was the most effective:

Last edited: