ELEVATOR SERVO CONTROL

Since I plan on using Solertex and painting this plane, I want to lighten the tail as much as possible.

So I stole an idea I saw on Al Walker's big 150cc plane (I think and Extra made in Germany) where he had mounted both elevator servos underneath the canopy.

I got some Carbon Fiber tubing that would allow the un-threaded part of a 4-40 rod to just barely slide in. I ground some notches into the un-threaded rod and liberally coated it with JB Weld. This made an assembly that is super stiff and impossible to pull apart.

To control the CF Tubing from flexing, I installed two nylon linear guides placed inside the back of the fuselage. I attached these guides by drilling tiny holes at various angels into the backside of the nylon guide and secured them with JB Weld. These nylon guides are from an old style of hinge system that would allow you to quickly disconnect the elevator from the stab. I've had them for 20 years and have no idea who made them. But the fit for the CF tubing was perfect, and being nylon they act as a self lubricating junction.

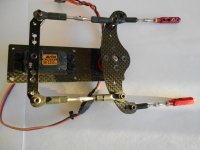

I mounted the Elevator Servo on a CF tray, identical to the one used for the Rudder Servo.

By using this technique I have moved 6 1/2 ounces from the tail to a position much closer to the CG of the airplane. The forward displacement of the two servos from the tail is 34 1/2 inches. That's a whopping change!