Dooinit

70cc twin V2

Dude, nice! those fuse sides are probably super straight. That's a great idea.Last time on build I mentioned spline sanding. For me I just ran the fuse side through my drum sander. But for you that don’t have one of these you can set up a long flat board with sand paper glued to it and run the fuse side back and forth as I show in 42% build pic. If your careful and apply even pressure you can use a flat short board or aluminum plate with sand paper glued to it. Start at one end of fuse and in one pass slide sanding board to the other end with even pressure.

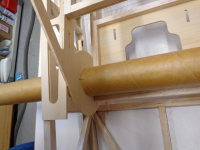

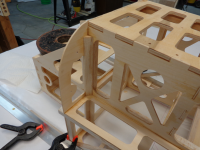

Next was gluing on the anti rotational ply plates and the stab tube ply to fuse sides.

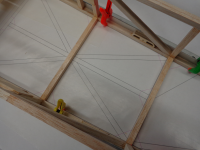

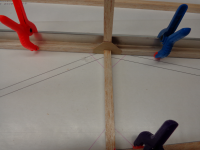

After this it was time to set the motor box and fuse side up in the fixture and start on the cross and diagonal braising. First though I wanted to set the wing tube fuse plates in place. At this time I’m not gluing in the wing tube socket yet. I’m just using it for location of the tube plates. I’ll install that a little later. There is a little sanding on 3/8” balsa that needed to be done first to slide the tube through motor box.

View attachment 6991 From 42% Build

View attachment 6982 View attachment 6983 View attachment 6984 View attachment 6985 View attachment 6986 View attachment 6987 View attachment 6988 View attachment 6989 View attachment 6990