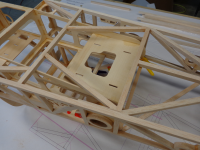

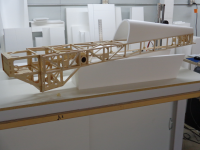

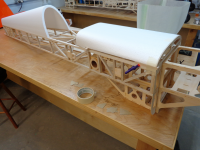

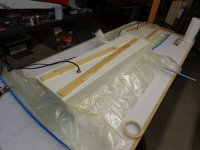

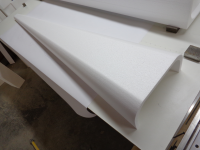

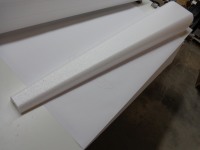

Bipenut

70cc twin V2

Also want to say thanks for fallowing and thanks to all that have purchased kits from us this year. In advance HAPPY NEW YEAR!

Thanks to you and Terry for making some nice kits. I would love to see a 100cc biplane kit.

Also want to say thanks for fallowing and thanks to all that have purchased kits from us this year. In advance HAPPY NEW YEAR!