IMAC Delro 2.5M Raven Build

- Thread starter Wacobipe

- Start date

HRRC Flyer

GSN Sponsor Tier 1

Hey @Wacobipe,

I feel your pain, Buddy. You're making more progress on your Raven than I am on my AMR Stick. . . .

Jetpainter

640cc Uber Pimp

It's hard to get much done in the workshop when it's flying season.

Alky6

150cc

Progress is progress! Looking good!

Wacobipe

100cc

My problem is I'm not getting much flying done either! Work is killing me this year and even when I do have time I can't muster the energy.It's hard to get much done in the workshop when it's flying season.

Last edited:

Wacobipe

100cc

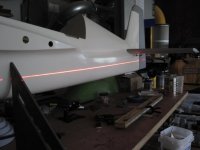

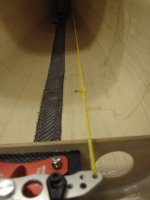

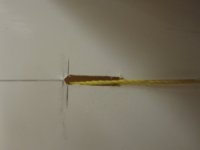

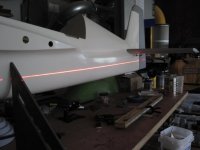

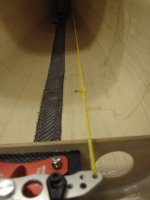

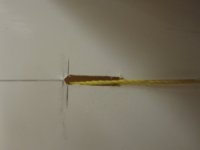

So I took the suggestions of some here and others at the field and came up with a pretty straight forward method of determining exactly where the pull-pull cable will exit the fuselage.

I determined that I could ID the height of the servo control arm in relation to the bottom of the fuselage. I leveled the bottom of the fuselage (not flight level, the bottom surface of the fuse). This allowed me to use a level and a straight edge on the outside of the fuse and mark the side of the fuse at the same level as the servo control horn on the inside. I then used my laser level to draw a line down the fuse side from my mark on the fuse back to the rudder horn. This line indicated position of the pull-pull cable from front to rear. From there, I used a set off calipers to set to the width of the control horns (both the servo and rudder are identical in width) to ID where that exit hole would be on the fuse by moving the calipers forward until they touched both sides of the fuse. I am not crossing the cables so this was easy, crossed cables will throw a curve ball at this approach as you'll need to ID the cross point inside to id the correct exit location. At this point I drilled a small hole and SUCCESS! My hole was perfectly located for the pull-pull at neutral. From there I just elongated the hole backwards until it cleared the cable at full throw as well and done!

Very pleased with the results and the very small opening I was able to achieve.

I determined that I could ID the height of the servo control arm in relation to the bottom of the fuselage. I leveled the bottom of the fuselage (not flight level, the bottom surface of the fuse). This allowed me to use a level and a straight edge on the outside of the fuse and mark the side of the fuse at the same level as the servo control horn on the inside. I then used my laser level to draw a line down the fuse side from my mark on the fuse back to the rudder horn. This line indicated position of the pull-pull cable from front to rear. From there, I used a set off calipers to set to the width of the control horns (both the servo and rudder are identical in width) to ID where that exit hole would be on the fuse by moving the calipers forward until they touched both sides of the fuse. I am not crossing the cables so this was easy, crossed cables will throw a curve ball at this approach as you'll need to ID the cross point inside to id the correct exit location. At this point I drilled a small hole and SUCCESS! My hole was perfectly located for the pull-pull at neutral. From there I just elongated the hole backwards until it cleared the cable at full throw as well and done!

Very pleased with the results and the very small opening I was able to achieve.

Last edited:

Jetpainter

640cc Uber Pimp

Nice work.

Alky6

150cc

+1. Very well done!!Nice work.

Wacobipe

100cc

I am rather embarrassed to return here and discover it has been almost a year since I posted any progress (because I have not really made any)  ...not to mention I started this build in 2014...Pathetic!

...not to mention I started this build in 2014...Pathetic!

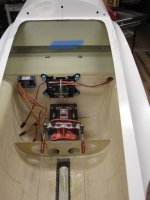

Anyway, progress is being made and I am very near completing all details and beginning the paint prep process! At this rate I should have her in the air by 2030!

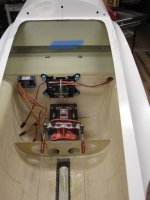

I've completed servo setups for the carb. I've also built custom servo leads for all of the servos and built fiberglass tubes to house/protect the servo wires running to the tail and to the engine bay. Finally, I've built a couple G-10 sheet covers to seal the engine/canister bay from the electronics area of the fuselage. these will be either screwed into place or Velcro'd in so I can pull them off easily for access and maintenance.

There are no pictures but I also installed the pitot tube in the wing for the Jeti telemetry system for airspeed...I plan to set up my stick shakers as a stall warning system using the airspeed telemetry!

I'm waiting for fuel tanks to arrive (I need 2 small ones - plumbed together - in order to get them on the CG and keep them far enough away from the canister) so I can install them and I need to do a weight/balance to see where things stand at this point and to ID a battery starting location, then I think were ready to sand/prime/paint!

...not to mention I started this build in 2014...Pathetic!

...not to mention I started this build in 2014...Pathetic!Anyway, progress is being made and I am very near completing all details and beginning the paint prep process! At this rate I should have her in the air by 2030!

I've completed servo setups for the carb. I've also built custom servo leads for all of the servos and built fiberglass tubes to house/protect the servo wires running to the tail and to the engine bay. Finally, I've built a couple G-10 sheet covers to seal the engine/canister bay from the electronics area of the fuselage. these will be either screwed into place or Velcro'd in so I can pull them off easily for access and maintenance.

There are no pictures but I also installed the pitot tube in the wing for the Jeti telemetry system for airspeed...I plan to set up my stick shakers as a stall warning system using the airspeed telemetry!

I'm waiting for fuel tanks to arrive (I need 2 small ones - plumbed together - in order to get them on the CG and keep them far enough away from the canister) so I can install them and I need to do a weight/balance to see where things stand at this point and to ID a battery starting location, then I think were ready to sand/prime/paint!