HRRC Flyer

GSN Sponsor Tier 1

Hey @Wacobipe,

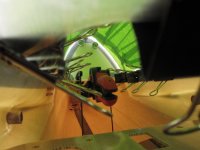

I was on RCSB last night reading a thread by someone building a 1/5 scale and a 1/4 scale Ziroli F9F Panther. The man found hatch covers where the servo actually mounted to the hatch like the one jetpainter shows above. The difference being, the hatch I saw actually had a molded cover over the servo arm so the only thing you saw from the outside was the control rod leaving the hole and connecting to the control surface. The one thing I'm not sure of is the hatch I saw would limit the servo travel to much for your Extra. If you'd like, I will go back through the thread and see if I can find where the hatch covers came from.

I cannot wait to see your raven finished. It's going to be AWESOME. . . . . . .

I was on RCSB last night reading a thread by someone building a 1/5 scale and a 1/4 scale Ziroli F9F Panther. The man found hatch covers where the servo actually mounted to the hatch like the one jetpainter shows above. The difference being, the hatch I saw actually had a molded cover over the servo arm so the only thing you saw from the outside was the control rod leaving the hole and connecting to the control surface. The one thing I'm not sure of is the hatch I saw would limit the servo travel to much for your Extra. If you'd like, I will go back through the thread and see if I can find where the hatch covers came from.

I cannot wait to see your raven finished. It's going to be AWESOME. . . . . . .