Wacobipe

100cc

It only took about 30 minutes with kitchen tongs, broom sticks, long pliers...and a bit of shaking to get all my clamps off and free the canopy!

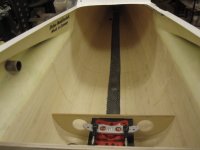

Here's a few photos. First are the pins in the front of the canopy (there is a ply doubler inside both the canopy and the fuselage to reinforce these pins as they are all that will hold the front of the canopy in place). Also there is a photo of the latch. I placed the latch in the fuse with the pin entering the canopy rather than the other way around because the latch mechanism is far less visible that way. Also, I can take the latch handle pin and modify that to look like an antenna or something like that to make it more scale looking!

Finally, a few pics of the fit of the canopy...pretty damn nice if I do say so myself...so maybe that clamping mistake was worth it!

Here's a few photos. First are the pins in the front of the canopy (there is a ply doubler inside both the canopy and the fuselage to reinforce these pins as they are all that will hold the front of the canopy in place). Also there is a photo of the latch. I placed the latch in the fuse with the pin entering the canopy rather than the other way around because the latch mechanism is far less visible that way. Also, I can take the latch handle pin and modify that to look like an antenna or something like that to make it more scale looking!

Finally, a few pics of the fit of the canopy...pretty damn nice if I do say so myself...so maybe that clamping mistake was worth it!

Last edited: