You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AeroWorks 150cc Ultimate

- Thread starter acerc

- Start date

acerc

640cc Uber Pimp

Today was a good day, now that it is over with anyway. First off the rest of the items needed for this assembly showed up. And just as important, the demo of the home is complete. So tomorrow, after a visit to the dentist, I can resume putting this "big" Ultimate together. And as it stands I should have the weekend, unobstructed, to work on it. Woo Hoo!!

Attachments

acerc

640cc Uber Pimp

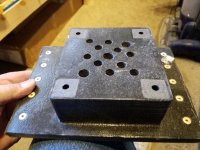

Being as the top engine mount is right on the corner of the engine box (pic 1) I am doing an offset mount with 1/4" ply (pic 2). Gerhard has some made of aluminum but I don't see one listed for this engine. So I will carry on with everything else until I can reach him before drilling the firewall.

Attachments

stangflyer

I like 'em "BIG"!

If I may, I am not sure I would go this route. The 150 has a ton of "pull" power. I think I would be afraid of the ply plate fracturing. It may be ok and others have no doubt done something similar. What I would rather see you do, (and have done) use solid stand offs from the firewall to the engine. Yes, I know...3w recommends bolting the engine to a perfectly flat firewall. And when possible, I will do so. But in your case where the firewall is already in place, either build a solid wooden mount the exact outside dimension of the engine and then mount both to the firewall. I really doubt you'll add that much weight. This is the one I built for the original Behemoth Yak.Being as the top engine mount is right on the corner of the engine box (pic 1) I am doing an offset mount with 1/4" ply (pic 2). Gerhard has some made of aluminum but I don't see one listed for this engine. So I will carry on with everything else until I can reach him before drilling the firewall.

This was pretty extreme because originally I had mounted the tank 3w 210csts. When I rebuilt the nose and installed the 212 quad, that changed. I'm sure Secraft makes an aluminum mount for that engine. But for cost effectiveness, I'd probably build one. Lighten it and you'll probably be around 8 ounces or less. In fact probably the same weight or less than what you are showing in your photos. I didnt look well enough at your photos. Does the firewall have aluminum angle braces supporting it to the sides of the motor box? If not, you'll thank yourself for putting them in. Balsa tri stock is not enough for the grunt of a dub.

Snoopy1

640cc Uber Pimp

That is a big plane you do not realize it until it is stood up like that. You almost had to put an extension to the shop.Been contemplating how I want to mount the engine as the engine mounts are, in a way, to big. Will find out here shortly as the fuse is on end and ready to start the mount.

acerc

640cc Uber Pimp

You misunderstand my issue, the top engine bolt splits the outside corner of the firewall, see pic 1. I took another quick peek and was wrong , there is no lip so I could add another 1/4ply instead of the spacer. Then epoxy the two 1/4 plies to the original firewall after cutting a notch out (pic 2) for the top bolts. The bottom bolts could run through all for 1/4 plies.If I may, I am not sure I would go this route. The 150 has a ton of "pull" power. I think I would be afraid of the ply plate fracturing. It may be ok and others have no doubt done something similar. What I would rather see you do, (and have done) use solid stand offs from the firewall to the engine. Yes, I know...3w recommends bolting the engine to a perfectly flat firewall. And when possible, I will do so. But in your case where the firewall is already in place, either build a solid wooden mount the exact outside dimension of the engine and then mount both to the firewall. I really doubt you'll add that much weight. This is the one I built for the original Behemoth Yak.

View attachment 109183 View attachment 109184

This was pretty extreme because originally I had mounted the tank 3w 210csts. When I rebuilt the nose and installed the 212 quad, that changed. I'm sure Secraft makes an aluminum mount for that engine. But for cost effectiveness, I'd probably build one. Lighten it and you'll probably be around 8 ounces or less. In fact probably the same weight or less than what you are showing in your photos. I didnt look well enough at your photos. Does the firewall have aluminum angle braces supporting it to the sides of the motor box? If not, you'll thank yourself for putting them in. Balsa tri stock is not enough for the grunt of a dub.

Attachments

Last edited:

49dimes

Damn I'm hungry

I would make two plates of the correct dimensions and height and glue them to the front and back of the existing firewall. Just make a spacer piece to get glued at the top between the two plates. Of course you will need to remove some of that motor box top and cover. Just reframe it and build it up to match the height of the new fire wall and make a new cover. Will look factory that way and you can bolt directly to it plus have a really beefy firewall for that Brutus 150  .

.

Last edited:

stangflyer

I like 'em "BIG"!

Ah! Ok, I understand now. As long as the motor bolts in some fashion to the existing firewall and is completely true on all four corners of the engine case, anything you do will be fine.You misunderstand my issue, the top engine bolt splits the outside corner of the firewall, see pic 1. I took another quick peek and was wrong , there is no lip so I could add another 1/4ply instead of the spacer. Then epoxy the two 1/4 plies to the original firewall after cutting a notch out (pic 2) for the top bolts. The bottom bolts could run through all for 1/4 plies.