AKNick

640cc Uber Pimp

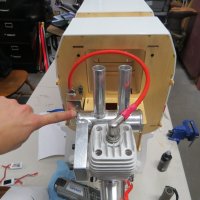

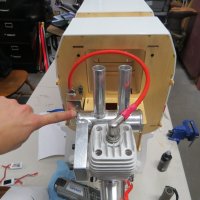

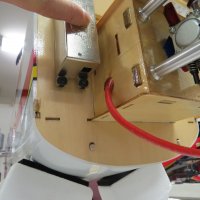

Still working on the Cowling. Had to decide where to put the DA Ignition Box so I could orientate the lead and plug cap accordingly.

I came up with this, just like how it lays out, with the connections pointing up, and the ignition box LED will be visible through the cowling inlet.

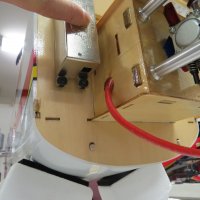

Then I got my pencil out, and cut with a dremel until I reached a point where the cowling would fit on.

Also opened up the cowling around the cooling fins a bit.

Eventually I'll open everything up a bit more, I just like to cut small first so I don't ruin a cowling.

I came up with this, just like how it lays out, with the connections pointing up, and the ignition box LED will be visible through the cowling inlet.

Then I got my pencil out, and cut with a dremel until I reached a point where the cowling would fit on.

Also opened up the cowling around the cooling fins a bit.

Eventually I'll open everything up a bit more, I just like to cut small first so I don't ruin a cowling.