You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pilot 40% 330 Recover and Build

- Thread starter stangflyer

- Start date

stangflyer

I like 'em "BIG"!

I have bought a number of replacement sets of gear. Strange though... I can't honestly remember if they've been pre-drilled or not. Lol...wow. Great memory huh? I'm leaning to being pre-drilled because if I had any heartburn over having to drill them, I would probably remember having to do so. I am pretty sure they all come pre-drilled for the specific airframe.Dear sir have you ever bought new landing gear for one of you 40% planes from pilot. If you have were they pre drilled or blank on holes.

Anything I can help with?

stangflyer

I like 'em "BIG"!

First test fit of my newly custom cut by Shay-mess 330 cowl. It's perfect and fits like a pair of painted on blue jeans on a hard bodied red head. Yeah, dang sexy too. I even got the exhaust outlets roughed in, choke rod hole drilled aaaaannnnd, intended vent holes penned onto the bottom shell. My son didn't get around to opening up the air inlets on the front of the cowl so I thought I might do that. But after test fitting the cowl I see the beast 157 cylinders are perfectly positioned 50% above bottom lip of cowl inlet. Once baffled, there should be no reason to cut larger inlet holes. I'm off to D&B for retaining bolts. When I return, we'll get to opening the bottom cowl vent and start prepping for primer.

More to come gents.

More to come gents.

pawnshopmike

Staff member

Getting so close! The suspense is killing me!

stangflyer

I like 'em "BIG"!

Yeah... me too. I can hardly wait to see it all together and flight ready.Getting so close! The suspense is killing me!

stangflyer

I like 'em "BIG"!

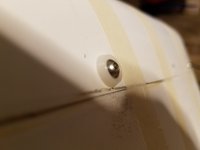

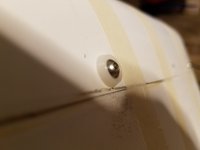

I made really good progress tonight. Located the correct size plugs for the side of the motor box and secured the Airman wheels with a retaining bolt. I've heard the White Rose axles with the "C" clips have a tendency to self launch when you least expect it. I've heard of many guys losing their high dollar aluminum wheels. Not this boy. I put the clips on then double secure the wheels with a bolt and oversize washer. I also drilled support bolt holes in the upper part of the now lower cowl half. Normally split coals already have them installed. Being an original non split cowl, I needed to install bolts and blind nuts. I also got the vent holes in the bottom of the cowl. Extra air to breath never hurt no red head. Plus. I now have the holes drilled in the cowl halves to keep them joined. I located some really cool counter sunk nylon washers for the Allen head bolts to sit in. I don't like the idea of bolts gouging deep into fresh paint.

Tomorrow after I return from the field, the cowl will get a really nice warm bath then wiped down with alcohol and set aside to air dry. We shoot primer tomorrow everyone. Maybe even some color. We'll see how it goes. Till then, have a good night. Time for me to wash off fiberglass dust and hit the sack.

Tomorrow after I return from the field, the cowl will get a really nice warm bath then wiped down with alcohol and set aside to air dry. We shoot primer tomorrow everyone. Maybe even some color. We'll see how it goes. Till then, have a good night. Time for me to wash off fiberglass dust and hit the sack.

Snoopy1

640cc Uber Pimp

I made really good progress tonight. Located the correct size plugs for the side of the motor box and secured the Airman wheels with a retaining bolt. I've heard the White Rose axles with the "C" clips have a tendency to self launch when you least expect it. I've heard of many guys losing their high dollar aluminum wheels. Not this boy. I put the clips on then double secure the wheels with a bolt and oversize washer. I also drilled support bolt holes in the upper part of the now lower cowl half. Normally split coals already have them installed. Being an original non split cowl, I needed to install bolts and blind nuts. I also got the vent holes in the bottom of the cowl. Extra air to breath never hurt no red head. Plus. I now have the holes drilled in the cowl halves to keep them joined. I located some really cool counter sunk nylon washers for the Allen head bolts to sit in. I don't like the idea of bolts gouging deep into fresh paint.

View attachment 104188 View attachment 104189 View attachment 104190 View attachment 104191 View attachment 104192 View attachment 104193 View attachment 104194 View attachment 104195 View attachment 104196 View attachment 104197 View attachment 104198 View attachment 104199

Tomorrow after I return from the field, the cowl will get a really nice warm bath then wiped down with alcohol and set aside to air dry. We shoot primer tomorrow everyone. Maybe even some color. We'll see how it goes. Till then, have a good night. Time for me to wash off fiberglass dust and hit the sack.

Question on the airman wheels normally the axel come with an E clips as you have described but then you stated that install a bolt into the end, does the axel come with threaded hole on the end if not how did you do that.

Snoopy1

640cc Uber Pimp

I have bought a number of replacement sets of gear. Strange though... I can't honestly remember if they've been pre-drilled or not. Lol...wow. Great memory huh? I'm leaning to being pre-drilled because if I had any heartburn over having to drill them, I would probably remember having to do so. I am pretty sure they all come pre-drilled for the specific airframe.

Anything I can help with?

I would like to ask for some advice. I built a AMR Stick a year ago, the Stick has 150 on the front and the weight is 40 lbs ready to take off, and have nothing but problems with the landing gear axles. The first set axels failed just taxing the plane for first time at the field. At the time I thought cheap Chinese steel. So replace the axels with 1/4 socket head screws. They worked but after the first landing they were bent. So replace the the axels with 3/8 socket head bolts and replaced the wheels with 8 inch diameter wheelsr from the 6 inch diameter wheel. Did about 10 flights with the plane and everything was great until yesterday. Came in for a landing and honestly it was good landing no bounce just a normal landing, as the plane landed both wheels snapped off landing gear bug in and flipped the plane and the two wheels rolled down the field, I was just absolutely dumb founded. I do not know what to do. It just does not make any sense it should be impossible to snap off two 3/8 bolts simultaneously like that.

stangflyer

I like 'em "BIG"!

Hey Snoops... "c"/"e" clip... all the same to me. If they don't make a complete circle they usually get what ever name I choose to call them. Lol. Seriously, the axles come pre-drilled and tapped when you get them. One of the reasons I have gone specifically to them over any other axle.Question on the airman wheels normally the axel come with an E clips as you have described but then you stated that install a bolt into the end, does the axel come with threaded hole on the end if not how did you do that.

The only planes I have, (Hangar 9 Sukhoi and Pilot Edge) are the only planes without the White Rose axles or aluminum wheels. I have them, just no time to swap it seems.

This is very odd to me. It is very hard for me to understand how a 40 lb plane is bending Axel's including the Big Bolt you have been putting in. Back approximately 5 years ago I did bend a set of white rose axles that were on my 260. Not severely, however enough that I could see once the plane was brought in that I had bent them. It was due to a very rough Landing. Since then, I have not had not one set of bent axles on any of my planes. Even my big Yak and my son's big Edge come in at over 50 pounds with fuel. We don't have any problems with bent axles on those planes. My guess is that the reason the wheels broke off is because when you drilled for the 3/8 bolt you took out too much meat on the landing gear and weakened the main absorption area, therefore too much forward load or sideload snap the landing gear. I really wish I could offer you something that would be helpful. In the photos that I have attached, you will see on my big Yak wheels that I am using, the same axles on it as I do all my other planes. No matter what size it may be. Would really like to know what you figure out on this dilemma.I would like to ask for some advice. I built a AMR Stick a year ago, the Stick has 150 on the front and the weight is 40 lbs ready to take off, and have nothing but problems with the landing gear axles. The first set axels failed just taxing the plane for first time at the field. At the time I thought cheap Chinese steel. So replace the axels with 1/4 socket head screws. They worked but after the first landing they were bent. So replace the the axels with 3/8 socket head bolts and replaced the wheels with 8 inch diameter wheelsr from the 6 inch diameter wheel. Did about 10 flights with the plane and everything was great until yesterday. Came in for a landing and honestly it was good landing no bounce just a normal landing, as the plane landed both wheels snapped off landing gear bug in and flipped the plane and the two wheels rolled down the field, I was just absolutely dumb founded. I do not know what to do. It just does not make any sense it should be impossible to snap off two 3/8 bolts simultaneously like that.