Not really "like everyone", like Pilot is pretty much it. Two other main industry leading ARF mfg's that I know of actually have pretty fair and / or adjustable geometry.

HI TERRY!

Tell me more! So far this summer I assembled the H9 Sukhoi (control horn pivot point over the hinge line, control horns drilled for approx. same height over the hinge line compensating for tapered wing/aileron, but not finely adjustable, and not able to offset for make throw), the AW Yak (pilot holes for control horn pivot point over the hinge line but not installed and adjustable for offset, 3 hole control horn for height adjustment due to tapering wings/ailerons but not finely adjustable), and this Pilot Extra which also has control horn pivot point over the hinge line and three holes for height adjustment due to the tapering wings/ailerons.

What H9 and Pilot don't give you is either 1) the control horns laterally in the correct place, or 2) and option to move them. You can mount the AW anywhere on the hard point. So with the AW you can get your leverage and your offset max throw correct. But, not your synchronization. None of the three offer perfect synchronization of servos as possible. Although, they are all probably relatively close. A bolt style control horn allows for fine adjustment and therefore perfect servo synchronization. It could be done with the style horns the three planes I mention use... but the manufacturers would have to understand it and work it out with the placement of the hardpoint.

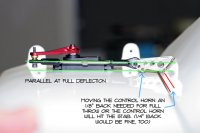

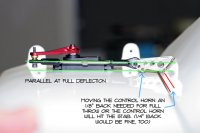

Here's what I'm looking for in terms of leverage and side load vs pry load:

Notice too, that I have my control horns wide spread for conicals. This should be standard, too.