You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scale RCM 1/3 Scale Champ Build

- Thread starter TonyHallo

- Start date

Bartman

Defender of the Noob!

A 5/8" round bad was cut to length and drilled and tapped for 4-40 screw to hold the short piece of 1/4" tube in place while silver soldering, this kept everything in proper alignment.

View attachment 108671

Two magnets were used to hold the tube in place while the 1/4" tube was silver soldered to the 5/8" tube, then the top joint was silver soldered, finally 1/16" sheet steel reinforce was added. This is when I learned that magnets loose their magnetism when heated above a certain temperature, I almost had the reinforcement tacked in when it fell out! I have several shifts on these struts already and still need to make the trailing links. The parts below are cleaned and fluxed, ready for heat.

View attachment 108688 View attachment 108671

what's the process for silver soldering steel parts together so that it's structural? i've used it on wire wrapped landing gear parts but never knew it would be used like brazing to hold stuff together without it being wire bound. Thanks! Great work, I'm ready to throw all my half assed **** away and just watch you artisan builders do your thing! lol

Bartman

Defender of the Noob!

Beautiful work, really just beautiful.Wasn't happy with the cabin roof so it was cut apart and re-glued. This time package tape was used for release rather than wax paper, it seemed to work out better. The wax paper kept tearing.View attachment 108689 View attachment 108690

Last edited:

Snoopy1

640cc Uber Pimp

Have to agree with you Stits is the only way to go, got info 3D two years ago and have building with Ultrcoat and really don’t like it the only thing going for it is that is lighter and quicker, and you can finish a plane during the winter months.Thanks, will try parchment paper in the future. The packaging tape worked well, the wings are separated and slide in freely once the packing tape was removed.

Can't wait to get the Stits on it!

TonyHallo

640cc Uber Pimp

what's the process for silver soldering steel parts together so that it's structural? i've used it on wire wrapped landing gear parts but never knew it would be used like brazing to hold stuff together without it being wire bound. Thanks! Great work, I'm ready to throw all my half assed **** away and just watch you artisan builders do your thing! lol

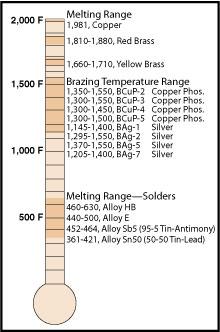

The solder used for wire wrapping is called silver bearing solder, it has a low percentage of solder, trade name Stay Bright. What I call silver soldering is actually silver brazing, it melts at a slightly lower temperature than bronze brazing rod, sorry for the confusion. The rod begins to melt just as the steel begins to show visible light. You can see the melting temperatures on the chart below. You need to get the metal hotter to flow a bronze brazing rod and light gauge parts can get over heated. The beauty of silver brazing is a propane torch is all you need.

TonyHallo

640cc Uber Pimp

Have to agree with you Stits is the only way to go, got info 3D two years ago and have building with Ultrcoat and really don’t like it the only thing going for it is that is lighter and quicker, and you can finish a plane during the winter months.

If you elect to use Steward Systems you can finish in the house since it is water based. Only problem is that it is not shipped in winter months due to freezing. I love the smell of MEK anyway!!!!

TonyHallo

640cc Uber Pimp

Made up a bender for the trailing link today from scrap metal.

And it worked!

The tube on the axle side was drilled with a F letter drill and 1/4" round bar was inserted into the tube before bending just in case any flattening occurred, but it did not.

Just a few more steps and the landing gear will be complete, thank goodness!!! Running out of things to do, still waiting on the spruce shipment from Aircraft Spruce. Can cut out a few bulkheads but hate to get too far ahead of the build , things don't always match the drawing as the build progresses.

And it worked!

The tube on the axle side was drilled with a F letter drill and 1/4" round bar was inserted into the tube before bending just in case any flattening occurred, but it did not.

Just a few more steps and the landing gear will be complete, thank goodness!!! Running out of things to do, still waiting on the spruce shipment from Aircraft Spruce. Can cut out a few bulkheads but hate to get too far ahead of the build , things don't always match the drawing as the build progresses.

Snoopy1

640cc Uber Pimp

Know the feeling being retired does have some drawbacks. I had access to a complete printing facility and cad drafting office sure miss it.One of the negative aspects of being retired is that now I must pay for copies of drawings. Had the 8 1/2" x 11" blown up 400% today for a total of $7.60, not bad. It will be easier scaling the elevator rib spacing since the drawing doesn't match the full scale.

View attachment 108708

Jetpainter

640cc Uber Pimp

There is a lot of really awesome workmanship in this thread, thanks for sharing it with us.!