WrongWayRc

50cc

I took a day off from flying to start to lay one up.

Airplane specs;

Wingspan 80.5 inches

Length 79.75 inches

Wing Area 2030

Typical flying weight 16.5 to 18 pounds depending on accessories and building style.

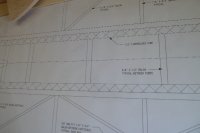

Full kit consists of all the build plans, all CNC router cut ribs, CNC Router cut center fuse section- carbon fiber wing tube and wing tube receiver, fuse tubes, all sticks, sheeting, hardwood and firewall. This kit has all wood needed to complete the airframe. The wing is removable for transport to and from the flying field.

Also included is custom 3/16 6061 T-6 main landing gear, 3.5 inch aluminum lite wheels(spun aluminum hub and rubberized plastic tread , WWRC no break axles, 3/16 Robart hinges, Custom WWRC G-4 double truss control horns designed for this plane (less weight, strong enough to fly a 40%), stainless capture ends and carbon rods for all controls including throttle, dubro HD ball links (2 per control horn), SAE 4-40 socket head bolts, washers and fiber lock nuts (basically a keeper hardware package including throttle linkage)

Airplane specs;

Wingspan 80.5 inches

Length 79.75 inches

Wing Area 2030

Typical flying weight 16.5 to 18 pounds depending on accessories and building style.

Full kit consists of all the build plans, all CNC router cut ribs, CNC Router cut center fuse section- carbon fiber wing tube and wing tube receiver, fuse tubes, all sticks, sheeting, hardwood and firewall. This kit has all wood needed to complete the airframe. The wing is removable for transport to and from the flying field.

Also included is custom 3/16 6061 T-6 main landing gear, 3.5 inch aluminum lite wheels(spun aluminum hub and rubberized plastic tread , WWRC no break axles, 3/16 Robart hinges, Custom WWRC G-4 double truss control horns designed for this plane (less weight, strong enough to fly a 40%), stainless capture ends and carbon rods for all controls including throttle, dubro HD ball links (2 per control horn), SAE 4-40 socket head bolts, washers and fiber lock nuts (basically a keeper hardware package including throttle linkage)