Notorious B.E.N.

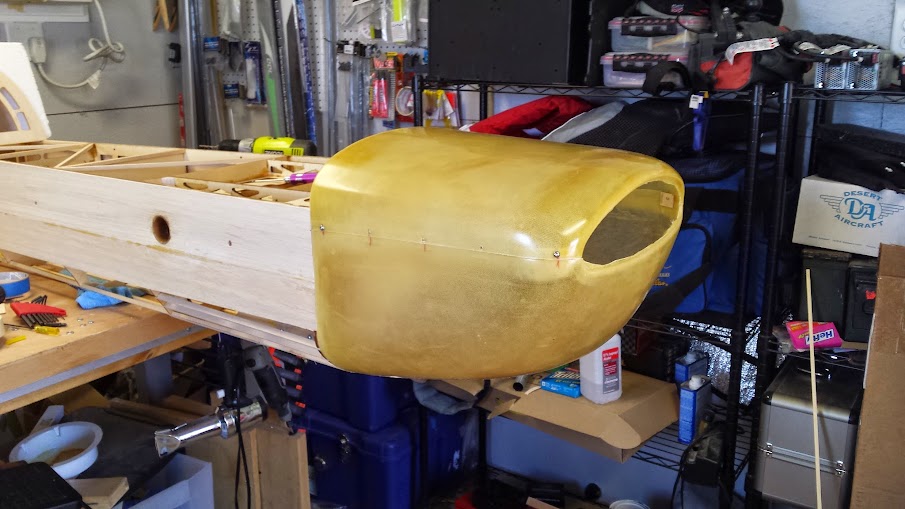

100cc

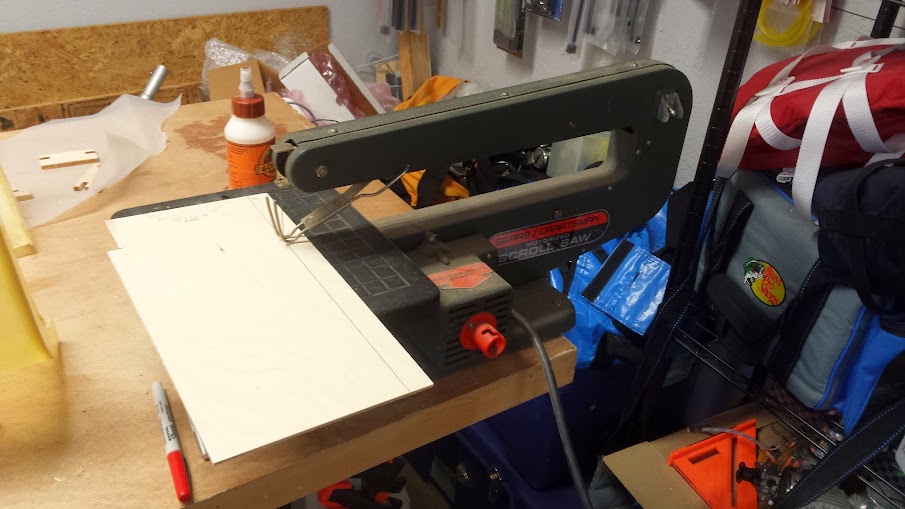

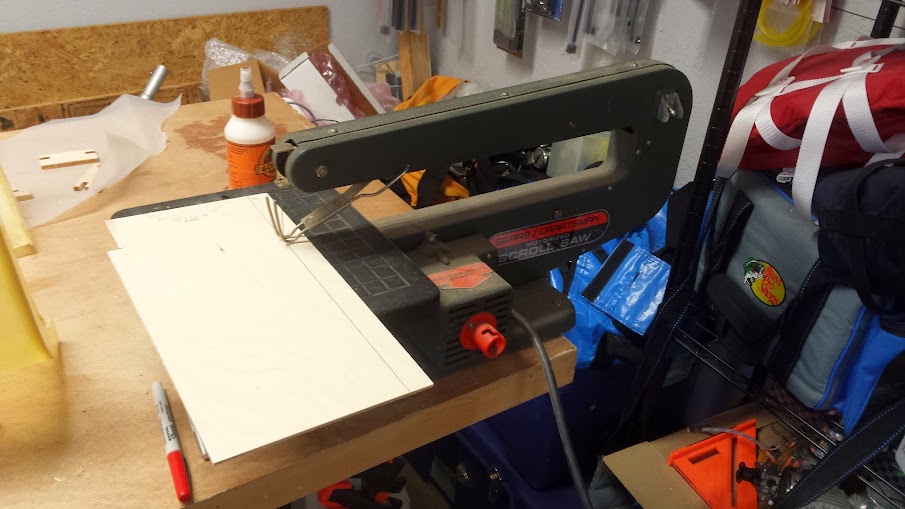

I began making some tabs for the back side of the lower cowl. Each was measured to be 3/4" by 1". I used scroll saw to cut it out. I don't know how old this is because I got it from my grandfather so probably mid-60's. Still works great though!

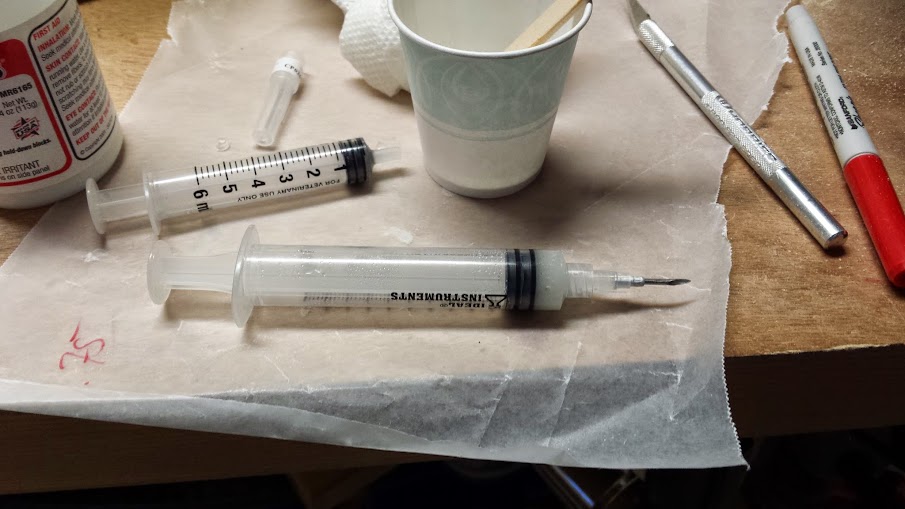

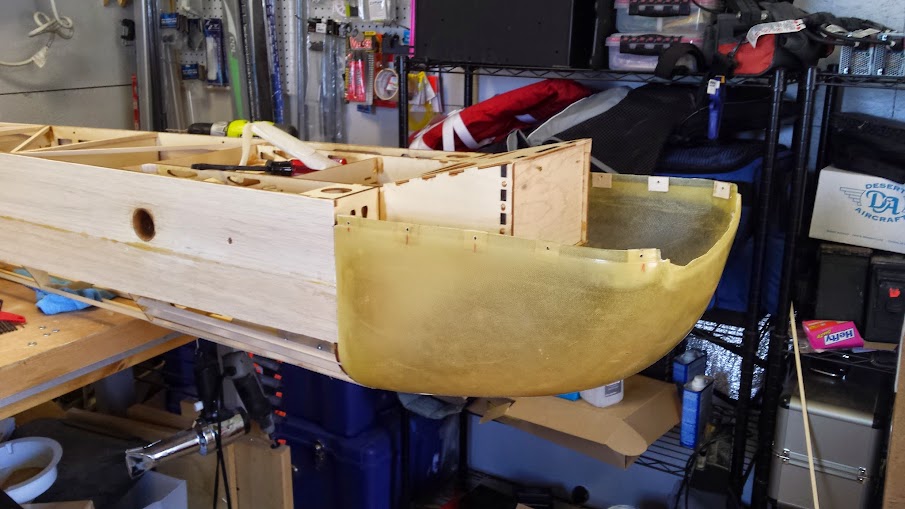

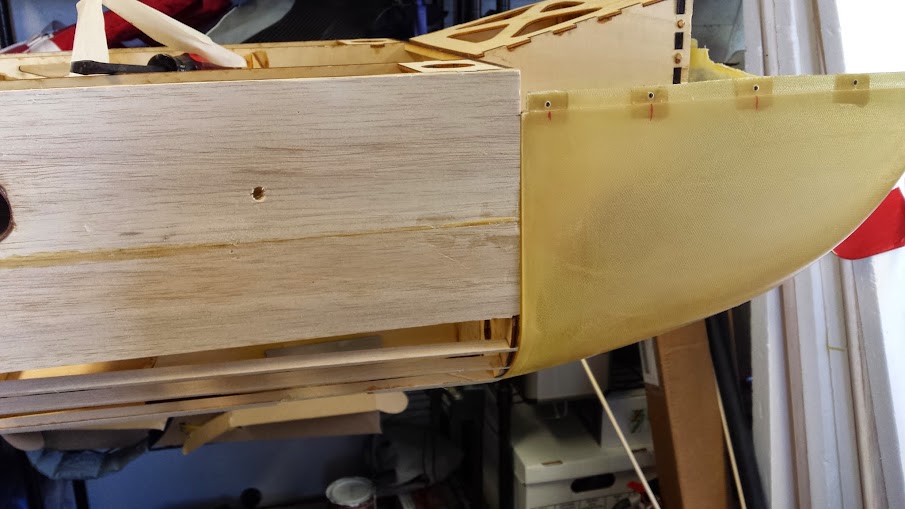

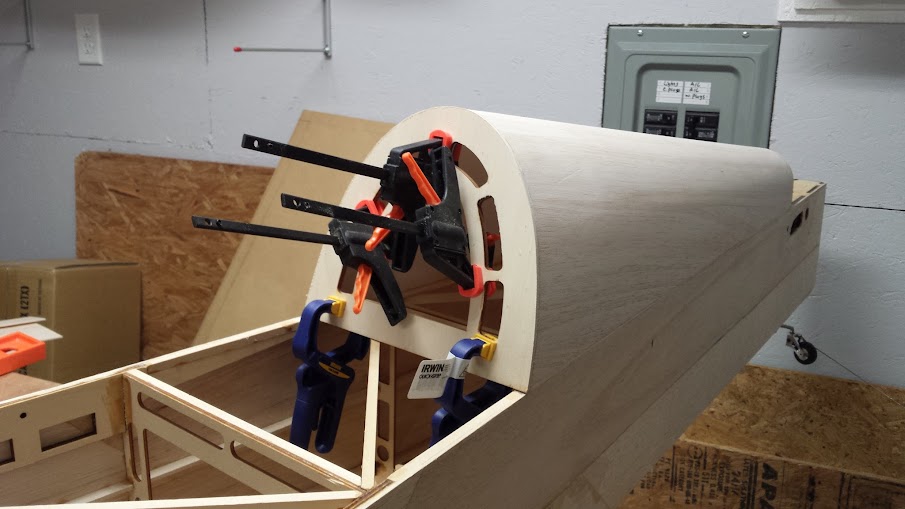

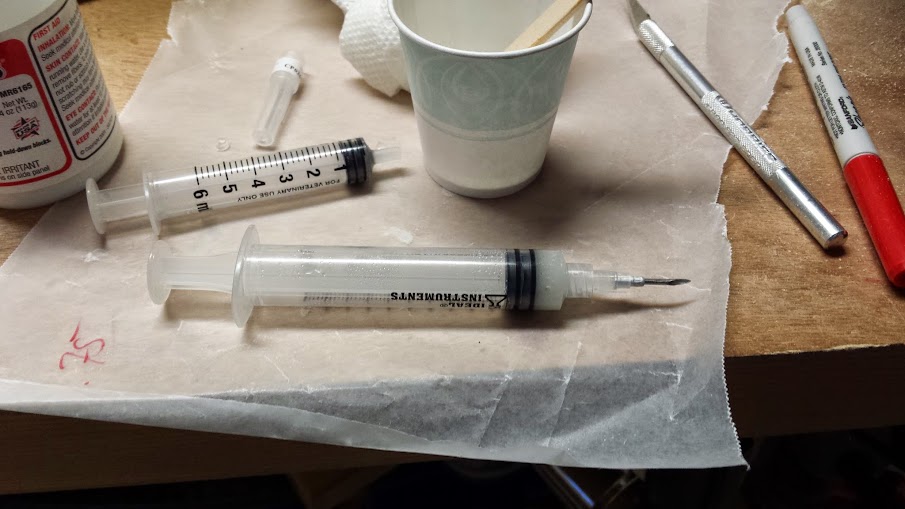

After I had the tabs cut, I mixed up some 30 minute Epoxy with milled fiberglass and began gluing them on. I used some of the small and cheap clamps from Harbor Freight to hold the tabs in place. For the two at the front, there was a small gap so I used a syringe and needle filled with the remaining epoxy mix to shoot it in the space between and to make a filet on the sides. This was to help keep it in place but primarily to help prevent crushing the fiberglass.

After I had the tabs cut, I mixed up some 30 minute Epoxy with milled fiberglass and began gluing them on. I used some of the small and cheap clamps from Harbor Freight to hold the tabs in place. For the two at the front, there was a small gap so I used a syringe and needle filled with the remaining epoxy mix to shoot it in the space between and to make a filet on the sides. This was to help keep it in place but primarily to help prevent crushing the fiberglass.