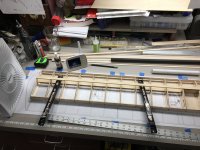

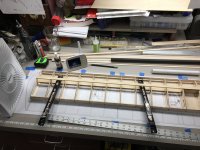

Working on the wing. Not sure why, but building over these plans kinda bother me because the variances in accuracy over the laser cut wood. David mentions this in his manual. So you use the plans as a guide and trust the wood. I’m not used to this.

There are steps in the manual with pictures made further in the build that you are at which is also misleading.

So read though it carefully. One thing that I thought would help when unbuild the other wing is to dry fit all the ply pieces like the servo bays to give you a better idea of where things need to go.

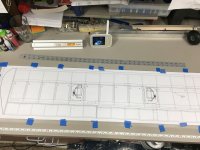

Note the inboard ribs are closer together when fitting the LE spar.

As mentioned in the manual, Mark where the cap strips go using the wood as a guide not the plans... doesn’t make much sense to use the plans other than squareness.

Razor saw is nice for this.

TE spar going in place

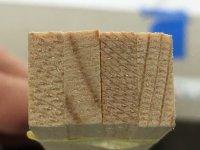

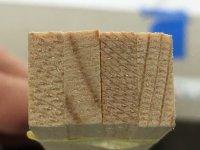

Here are the spars provided. Ugly grain.

One young growth spar is having a bad hair day. Glue should fix that along with poring it with an older spar.

LE spar with a scarf joint. Note there is a gap between the alignment marks.

Putting the 1/4-20 blind but in place.

The manual shows both sides flush... hmmm may have to trim it off.

Dry fitting

Starting to look like a wing.