You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D 75cc 106" HyperLITE Slick 540 by Fibertech N More

- Thread starter Fibertech

- Start date

Fibertech

70cc twin V2

When will kits be available?

The million dollar question. This build covers the first ever of the 35% to be built so I need to get through this part and make sure all fits as planned. I also need to produce a new cowl and will go through this in the build. My goal is to have this and maybe the second one built for maiden this spring. Then it needs some real flight testing done if there is no mods needed it could possibly be in

midsummer.

All will be posted on this thread so keep looking

Fibertech

70cc twin V2

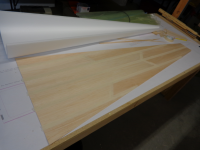

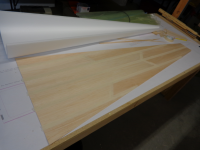

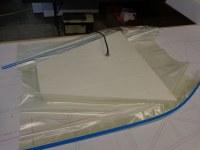

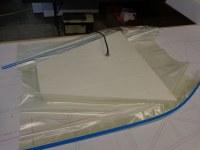

Time to sheet the belly pan. The first pic shows a easy way to do the scarf joint on balsa ends for those that don’t know this. Lay one sheet on top the other and cut a long angle through both sheets at same time. This makes a nice true end joint. The rest if really straight forward so wont explain to much. Just roll the foam from center to one side and mark and cut the long sides.

The bagged part came out realy nice

The bagged part came out realy nice

Fibertech

70cc twin V2

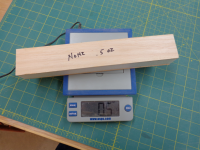

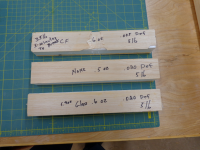

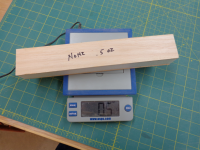

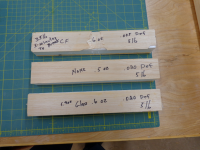

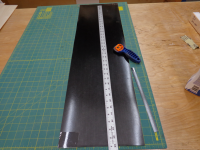

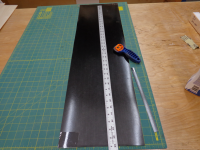

There has been a lot of use of CF these days compared to yester years. I wanted to do some testing of CF vrs Glass cloth or nothing at all for lightning of foam parts. I cut two 2” x 12” foam blocks for the tests. One block has a ½” wide CF strip the length of the block. The second has the a ½” wide glass cloth x length of block and third has no glass no CF. The three blocks were all sheeted with west systems epoxy and then vacuum bagged.

The test bench is a little crude but good enough to see what the deflection vrs weight would read. The weight was 5lb hung in the center.

These were the readings

Block with glass: weight 6oz. deflection .020”@5lbs

Block with CF: weight 6oz. deflection .005”@5lbs

Block with nothing: weight 5oz. deflection .020” @5lbs

So the block with CF was the overall winner in weight and deflection. In pic7 I had hung a 35lb plate on the cf and it took about 3 minutes before failing. Also note the blocks with cf and glass did not break through as I expected they wouldn’t compare to no cloth.

The test bench is a little crude but good enough to see what the deflection vrs weight would read. The weight was 5lb hung in the center.

These were the readings

Block with glass: weight 6oz. deflection .020”@5lbs

Block with CF: weight 6oz. deflection .005”@5lbs

Block with nothing: weight 5oz. deflection .020” @5lbs

So the block with CF was the overall winner in weight and deflection. In pic7 I had hung a 35lb plate on the cf and it took about 3 minutes before failing. Also note the blocks with cf and glass did not break through as I expected they wouldn’t compare to no cloth.

Fibertech

70cc twin V2

So after the foam testing I moved onto the rudder sheeting. I used the .007 pre-preg cf strips at about ½” wide on both sides. This should really strengthen the control surface after removing the cut outs to lighten.

Before sheeting I like to spray down the balsa with cheap hair spray to slow down the epoxy from penetrating through. I use west systems’ slow set epoxy again for this. I also marked both sides of foam were the cf strips needed to be. This saves time when gluing as I don't pre glue these strips down. I do rough sand the cf pre preg. I think this will allow better glue bond.

Before sheeting I like to spray down the balsa with cheap hair spray to slow down the epoxy from penetrating through. I use west systems’ slow set epoxy again for this. I also marked both sides of foam were the cf strips needed to be. This saves time when gluing as I don't pre glue these strips down. I do rough sand the cf pre preg. I think this will allow better glue bond.

Terryscustom

640cc Uber Pimp

Cool test with the CF and Glass. Curious what type of CF (cloth or unidirectional plate) and what weight FG cloth?

Fibertech

70cc twin V2

The CF was 5.9oz plain weave for this test. I just got the pre preg the other day and will do same test with it.Cool test with the CF and Glass. Curious what type of CF (cloth or unidirectional plate) and what weight FG cloth?

boggintuff

50cc

Is this going to be in a kit version or ARF version?